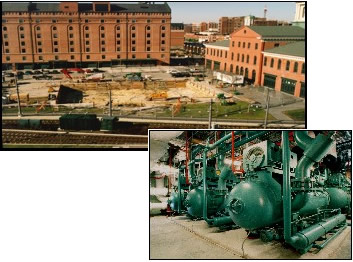

Comfort Link Plant I, Baltimore, Maryland

Design/Build Services: Mechanical & Piping Installation

The Industrial Facility Project

Comfort Link, formerly a general partnership between Constellation Energy subsidiary Baltimore Gas and Electric Company and EMCOR Group, Inc., has been providing district cooling services to buildings in the downtown Baltimore business corridor since 1996. Its customers include federal, state, and local government buildings, entertainment and retail establishments, commercial office buildings, hotels, hospitals, religious and other non-profit facilities.

In the 1996, Comfort Link sought to build its first local district cooling plant, Plant I, in the Baltimore Convention Center (BCC). The plant consists of 5,400 tons of chiller capacity, and 30,000 ton hours of underground thermal storage located in the basement of the Baltimore Convention Center. Plant I produces 8,000 exportable tons serving a wide range of clients. The Comfort Link district commercial cooling service has drawn several long-term contracts including The Maryland Stadium Authority, which has a service agreement for 5,325 tons of chilled water to meet its’ cooling needs for the Baltimore Convention Center thru 2017.

Poole & Kent Mechanical Contractor Role

In our role as the prime mechanical contractor, Poole and Kent constructed the plant in two phases to comply with the start up and operation of the newly constructed Baltimore Convention Center.

Phase I – Mechanical Equipment Installation

(6) Rotary Screw Compressors - 990 Nominal Duty/660 Ton Ice Duty

Phase II – Mechanical Equipment Installation

30,000 ton-hours BAC Ice Thermal Storage Coils

In Phase II, Poole and Kent installed the following equipment to increase the Plant I ton-hours by 20,000 ton hours of ice storage located in the basement of the Baltimore Convention Center.

This work was completed in March 1997 for a combined total 50,000 ton-hours of thermal ice storage. Additionally, Poole and Kent was responsible for the installation of over 2,000 feet of distribution piping for the supply and return of chilled water to Plant I.

Challenges / Achievements / Awards

The initial design for this fast-track, design/build project did not support the maximum operation of Plant I. The chilled water facility was nearly three times the size of the original design. To achieve maximum results, Poole and Kent worked closely with the Engineer to resolve issues and ensure proper egress of the equipment.

It was also necessary for Poole and Kent to coordinate closely with City authorities so that underground construction activities for the underground distribution piping could be performed on major city thoroughfares.